Advanced Production Technology

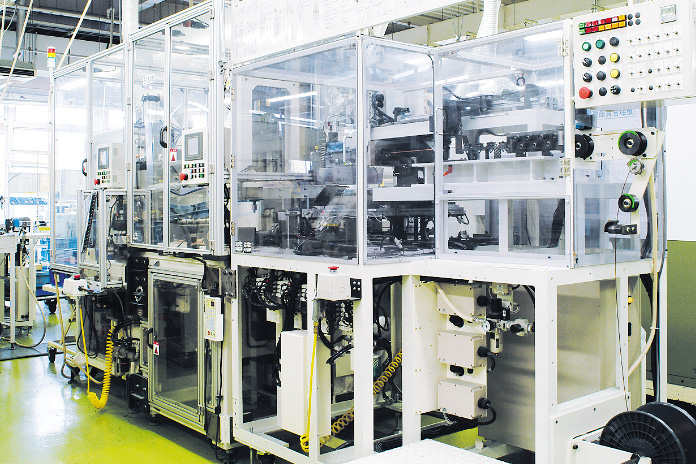

An environmentally-friendly and highly efficient production system creates optimum harmonization between people and production equipment.

Designed to accommodate not only mass production but small-lot, multi-batch production as well, our systems handle a diverse range of production configurations. From winding, machine tooling, resin molding and critical-component assembly processes all the way to the inspection process, we constantly take on the challenge of new construction methods and equipment development that drive both high efficiency and an approach that is people- and environment-friendly.

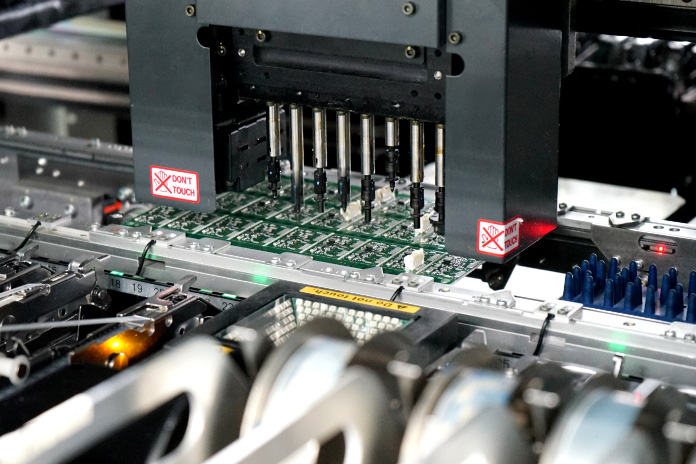

Production Engineering for equipment

- Simulation of SMT production

- Simulates efficient mounting procedures for surface mounted parts in order to shorten cycle time.

Principal Equipment and Lines

- Coil assembly line

- This is an automatic coiling machine capable of winding coils both thin and thick.

- PAS Drive unit assembly Line

- This line is where we produce the PAS drive unit, the heart of the electro-hybrid bicycle.

- Rotor machining and assembly line

- This line is designed for labor-saving operation, and makes it possible for one person to oversee everything from machining and assembly to inspection.

- Surface mounting line

- This line is where we produce various types of control PCBs. We also have clean rooms at our facilities.

YAMAHA MOTOR ELECTRONICS CO., LTD.

1450-6 Mori, Mori-machi Shuchi-gun Shizuoka 437-0292 Japan

Fax:81-538-85-0591